by cpwinch

Share

Winches at the Waterfront – Key to Efficient Port and Wharf Operations

Experience

30+ Years Rich Experience

Digital Solutions

R&D Team standing by

24/7 Support

We are here for you

Modern ports and terminals demand precision, safety, and speed when handling cargo, docking ships, or positioning equipment. In this context, winch systems play a pivotal role — from mooring vessels securely to pulling heavy containers, winches provide the necessary force and control that cranes or tugs alone can’t offer.

Common Applications of Winches in Port Environments

1. Mooring and Anchoring

-

Tensioning and holding ship lines during docking

-

Automatic tension winches adjust rope tension as tides rise and fall

-

Installed on quay walls, mooring dolphins, or bollard platforms

2. Cargo Handling and Transfer

-

Assisting in the positioning of containers or cargo trailers

-

Used with ship-to-shore systems to guide pallets or platforms

-

Supporting RO-RO (roll-on/roll-off) loading

3. Vessel Movement and Positioning

-

Pulling ships into dry docks or maintenance berths

-

Guiding barges or ferries into tight wharf areas

-

Assisting tugboats during docking or towing

4. Equipment Handling on Docks

-

Lifting or adjusting port maintenance tools, ramps, and platforms

-

Moving spare parts, motors, or structural frames for port machinery

Advantages of Using Winches in Port Operations

| Feature | Benefit |

|---|---|

| High Pulling Capacity | Moves large vessels or containers with ease |

| Controlled Operation | Variable-speed and brake systems ensure safety |

| Adaptable Mounting | Can be installed on decks, pylons, or recessed into floors |

| Weather Resistance | Marine coatings and IP-rated enclosures for corrosion control |

| Remote and Auto Controls | Supports manual, wireless, and automated winch systems |

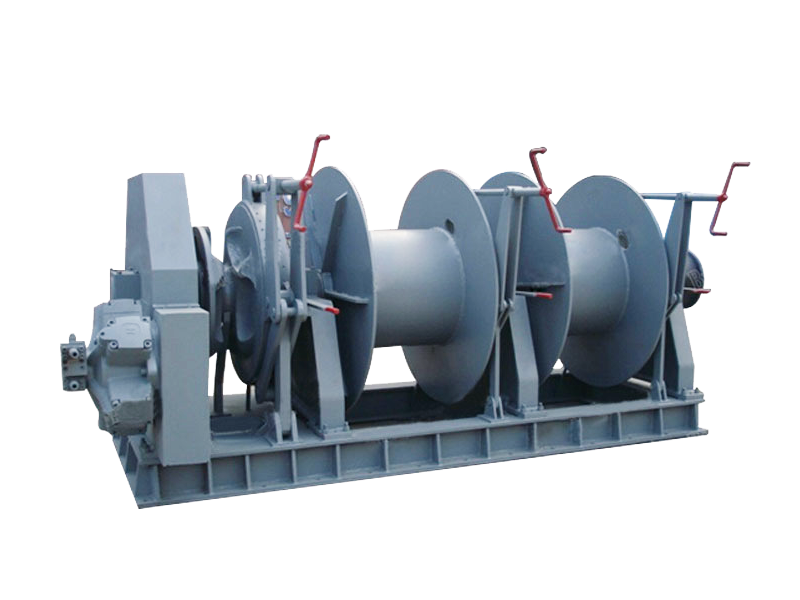

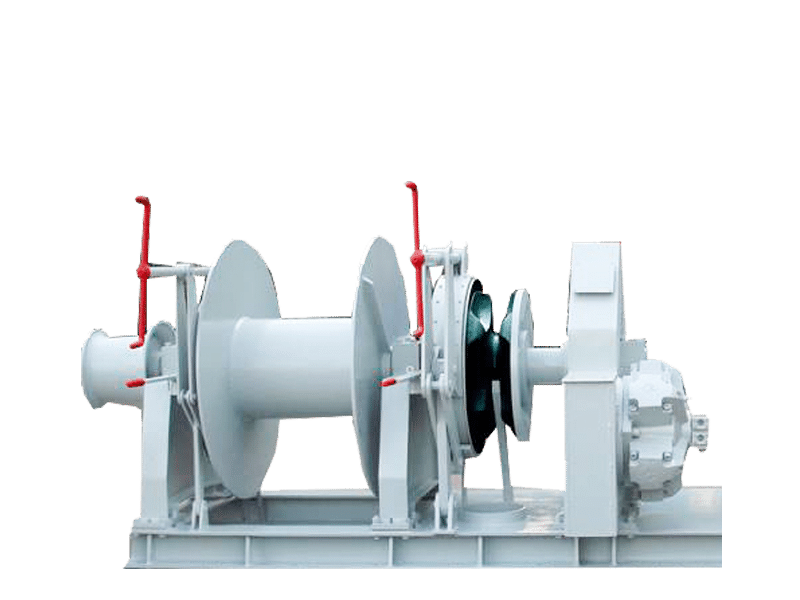

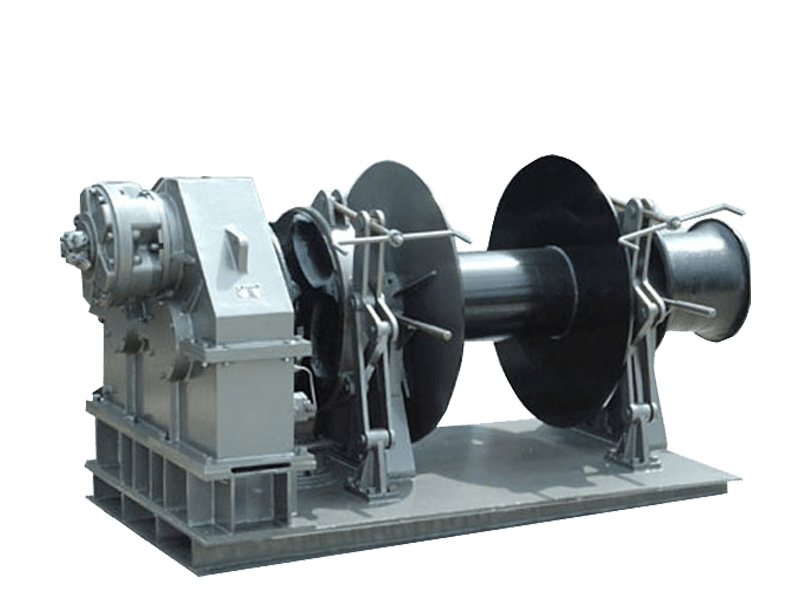

Types of Winches Used in Port & Wharf Operations

-

Mooring Winch: Designed for constant line tension and secure anchoring

-

Capstan Winch: Vertical drum winch ideal for quick line take-up on deck

-

Electric Cargo Winch: Efficient for load transfers and light-duty pulling

-

Hydraulic Dock Winch: High-power system for large vessel movement

-

Trolley Winch: Assists in guiding mobile cranes or rolling cargo platforms

Key Design Considerations for Port Winch Systems

To ensure a port winch system functions reliably, engineers and port authorities must consider:

-

Load requirement: Static holding or dynamic pulling

-

Line speed: For mooring vs. fast loading cycles

-

Control system: Manual joystick, pendant, or PLC-based automation

-

Braking method: Fail-safe brake, secondary mechanical brake, or dynamic braking

-

Environmental exposure: Salt spray, UV radiation, heavy rainfall

-

Integration compatibility: With SCADA systems or smart port control centers

CPWINCH – Your Port Winch Partner

CPWINCH designs and supplies custom winch systems for ports, shipyards, and terminal facilities worldwide. Our product advantages include:

-

Marine-grade materials and paint finishes

-

Load ranges from 3 tons to 200+ tons

-

Optional auto-tensioning and sensor feedback loops

-

Explosion-proof and waterproof models

-

Modular installation structures for docks and vessels

Whether you’re equipping a new terminal or upgrading legacy winch units, CPWINCH offers OEM and turnkey winch solutions tailored for high-volume port environments.

A Smarter, Safer Dockside with CPWINCH

Winches are more than pulling tools — they are critical components in port logistics and vessel operations. When properly selected and integrated, winch systems enhance efficiency, safety, and cost-effectiveness at every stage of the marine cargo cycle.

Frequently Asked Questions

Q1: What’s the difference between a mooring winch and a towing winch?

A1: Mooring winches hold a vessel in position at the dock, while towing winches are used to pull or reposition vessels during navigation or docking.

Q2: Can CPWINCH winches operate under saltwater conditions?

A2: Yes. Our winches are built with marine-grade finishes, stainless steel hardware, and IP65+ enclosures for long-term corrosion resistance.

Q3: Do you provide control systems with the winch?

A3: Absolutely. We offer full control kits including remote wireless, manual switchboards, or integrated PLC systems based on customer needs.

📩 Get a Free Quote

Whether you need a compact 1-ton winch or a heavy-duty 200-ton unit, CPWINCH Group is your go-to supplier. We support:

-

OEM Orders

-

Bulk/Wholesale

-

International Shipping

📧 Email: info@cpwinch.com

🌐 Website: www.cpwinch.com