by cpwinch

Share

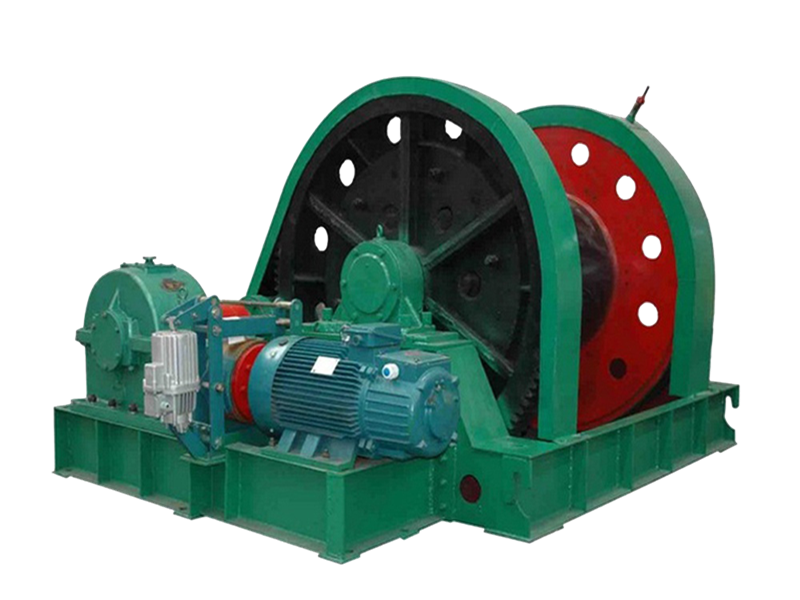

Why Electric Winches Are Essential for Modern Industrial Applications

Experience

30+ Years Rich Experience

Digital Solutions

R&D Team standing by

24/7 Support

We are here for you

Power and Precision — The Role of Electric Winches in Industry

In heavy industry, where safe and efficient handling of loads is critical, electric winches have become indispensable. From lifting steel beams in construction to pulling components in assembly lines, these winches offer a balance of strength, control, and automation that manual and hydraulic systems cannot match.

Industrial Use Cases of Electric Winches

Electric winches are widely used across various sectors. Here are some of the most common application areas:

1. Manufacturing and Factory Automation

-

Pulling production components along conveyor systems

-

Lifting molds or dies during equipment maintenance

-

Positioning heavy machinery for alignment or repair

2. Construction and Infrastructure Projects

-

Hoisting rebar cages, precast components, and scaffold systems

-

Lifting equipment to upper floors during high-rise construction

-

Winching materials over difficult terrain

3. Water Projects and Utility Work

-

Pulling sluice gates or maintenance tools

-

Assisting in the positioning of large pipelines

-

Lifting pumps or valves in water treatment plants

4. Shipbuilding and Port Equipment

-

Lifting anchor chains, propellers, or engine parts

-

Pulling sections of vessels into assembly position

-

Mooring support with electrical control

Advantages of Electric Winches in Industry

| Feature | Advantage |

|---|---|

| Consistent Power Output | Suitable for continuous-duty operations |

| Precise Load Control | Smooth start/stop, adjustable speed, and braking |

| Low Maintenance | Compared to hydraulic systems, electric winches are easier to maintain |

| Remote Operation | Supports wireless control or integration into automated lines |

Key Features to Look For in an Industrial Electric Winch

-

Load Capacity: Choose a winch with at least 20% safety margin above max load

-

Speed Control: Variable frequency drives (VFD) for smooth, adjustable hoisting

-

Duty Rating: Ensure the winch is rated for your usage frequency (e.g. M4, M5)

-

Brake System: Fail-safe electromagnetic or mechanical braking

-

Protection Rating: Choose IP54 or above for dusty/wet environments

-

Wire Rope System: High-tensile, anti-rotation cable for better winding stability

CPWINCH – Your Trusted Electric Winch Supplier

At CPWINCH, we offer a wide range of industrial-grade electric winches built to handle the harshest environments:

-

Load range: 1 ton to 100+ tons

-

Duty types: Intermittent and continuous

-

Control modes: Push-button control, pendant remote, or PLC integration

-

Optional features: Limit switches, load indicators, overload protection, rope guide systems

We provide customized OEM/ODM winch solutions for clients in manufacturing, construction, ports, utilities, and more.

A Smarter Way to Lift and Pull

Electric winches offer power, precision, and automation in one package — making them ideal for industrial users who value efficiency and safety. Whether you need to pull, lift, position, or hold heavy loads, an electric winch from CPWINCH will get the job done reliably.

Frequently Asked Questions

Q1: Can electric winches be used outdoors or in wet areas?

A1: Yes, as long as they have proper IP-rated enclosures (e.g. IP65) and anti-corrosion treatment.

Q2: What’s the difference between a lifting winch and a pulling winch?

A2: Lifting winches are built to handle vertical loads with strong brakes and rope management, while pulling winches are optimized for horizontal load movement.

Q3: Can your electric winches be customized for my production line?

A3: Absolutely. CPWINCH specializes in OEM winch solutions tailored to your technical and environmental needs.

📩 Get a Free Quote

Whether you need a compact 1-ton winch or a heavy-duty 200-ton unit, CPWINCH Group is your go-to supplier. We support:

-

OEM Orders

-

Bulk/Wholesale

-

International Shipping

📧 Email: info@cpwinch.com

🌐 Website: www.cpwinch.com